- Home

- Thibra

Product was successfully added to your shopping cart.

Product was successfully added to your comparison list.

-

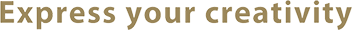

Endless possibilities for creative applications.

Thibra is a must-have for every hobbyist or professional making their own

objects or sculptures. This spectacular sheet material can be shaped over and

over again when heated with a hot air gun.

View our videos

The videos show the basic techniques for working with Thibra. How to make Thibra shapes using silicone molds, create Thibra shells, shape Thibra like clay etc. The videos show the endless possibilities of Thibra. View the videos and let them inspire you!

Hobby & Decoration

Thibra is the new malleable material for hobby and decoration. Heat Thibra to copy the shape of any existing product in your home (greased to

Read more...

Professional Art & Design

Thibra can immediately after de-greasing with warm water and soap be treated with (spray-)primer. After that you can (spray-)paint your object.

Read more...

Cosplay & Theatre

Thibra is a popular thermoplastic material and very suitable for making costumes, masks, harnesses, parts of decor and many other things.

Read more...

Advantages of Thibra

- Easy to heat and shape, doesn’t tear easily and is strong.

- Perfect for making double-curved and extreme shapes.

- After degreasing it can easily be (spray-)painted, printed and stamped.

- Unique: Thibra can be corrected and repaired by reheating, even when the object has cured already.

- Extremely smooth due to special composition, this prevents lengthy filling and sanding

- When heated, it combines well with other materials such as felt, textile, foam shapes. When cooled, contact adhesive can be used.

- Excellent alternative for expensive methods such as vacuum forming.

- Relatively small amounts needed for an object, leftovers can be recycled.

- Thibra can be processed in several layers and can afterwards be filled and sanded.

- Thibra is an innovative plastic of outstanding quality. It is affordable and offering a whole new range of possibilities in modelling and shaping.

- Thibra doesn´t necessarily need sanding. ´However, it can be done in order to eliminate small irregularities'.

Applications

- Costumes, masks, harnesses, props and parts of decor

- Jewellery, decorations, lampshades, bowls etc.

- Creating and repairing scale model items

- Prototype building, sculptures.

Thibra

Thibra was founded with the intention to present an excellent range of unique materials for industrial designers, prototype makers, professional artists, designers, theaters, costume- and prop makers, hobbyists and the cosplay community. Our mission is to create and sell thermoplastic materials for a wide variety of uses that are distinguished by the combination of premium quality, a reasonable price and excellent applicability.

Our Products

Contact

- Dutch Cast BV

- St-Elisabethstraat 86

- 5261 VS Vught - Nederland

- Phone: +316 531 963 66

Company Information

- E-mail address: info@thibra.com

- KVK: 63433222

- VAT: NL 8552 34 489 801

© 2018 Thibra. All Rights Reserved.